✈️ What Really Happens During an Annual Inspection at Pacific Aviation Solutions

“Aviation in itself is not inherently dangerous. But to an even greater degree than the sea, it is terribly unforgiving of any carelessness, incapacity or neglect.”

If you own a general aviation aircraft, you already know the annual inspection can feel a little mysterious.

Your airplane comes into the shop, we perform an initial run-up… panels come off… time passes… and then there’s a call with findings, recommendations, and decisions to make.

At Pacific Aviation Solutions, we believe the annual shouldn’t feel like a black box. Our goal is transparency — helping owners understand what we’re doing, why we’re doing it, and how it keeps you (and your aircraft) safe.

This post pulls back the curtain on what really happens during an annual inspection for aircraft like Cessna, Piper, Beechcraft, Van’s RVs, and other GA favorites.

Why the annual matters (beyond “because the FAA says so”)

Yes — the regulations require it. But the real purpose is prevention.

A thorough annual helps us identify:

Wear and fatigue long before failure

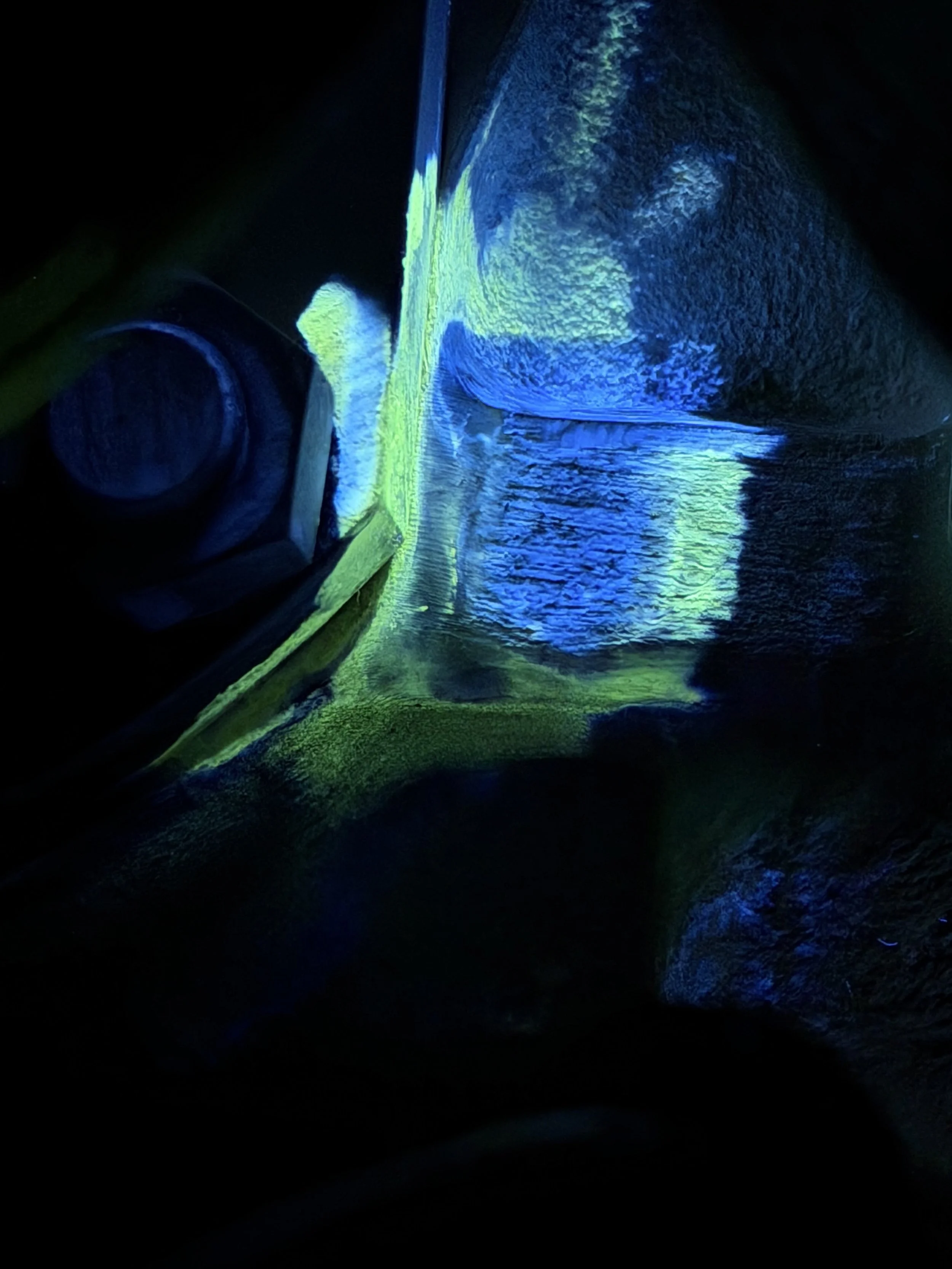

Corrosion hiding in seams and structure

Improper past repairs or missed maintenance

Small issues that can become expensive surprises later

Think of it as a detailed health check — one that protects both safety and aircraft value.

Step 1: Start with the story — logbooks and research

Before a wrench is turned, we sit down with the paperwork.

We review:

Airworthiness Directives (AD) compliance

Previous discrepancies

Maintenance and modification history

Inspection intervals coming due

Service bulletins relevant to your make/model

Logbooks tell the story of the airplane — and they help us know where to look more closely.

Step 2: Open it up — inspect, photograph, document

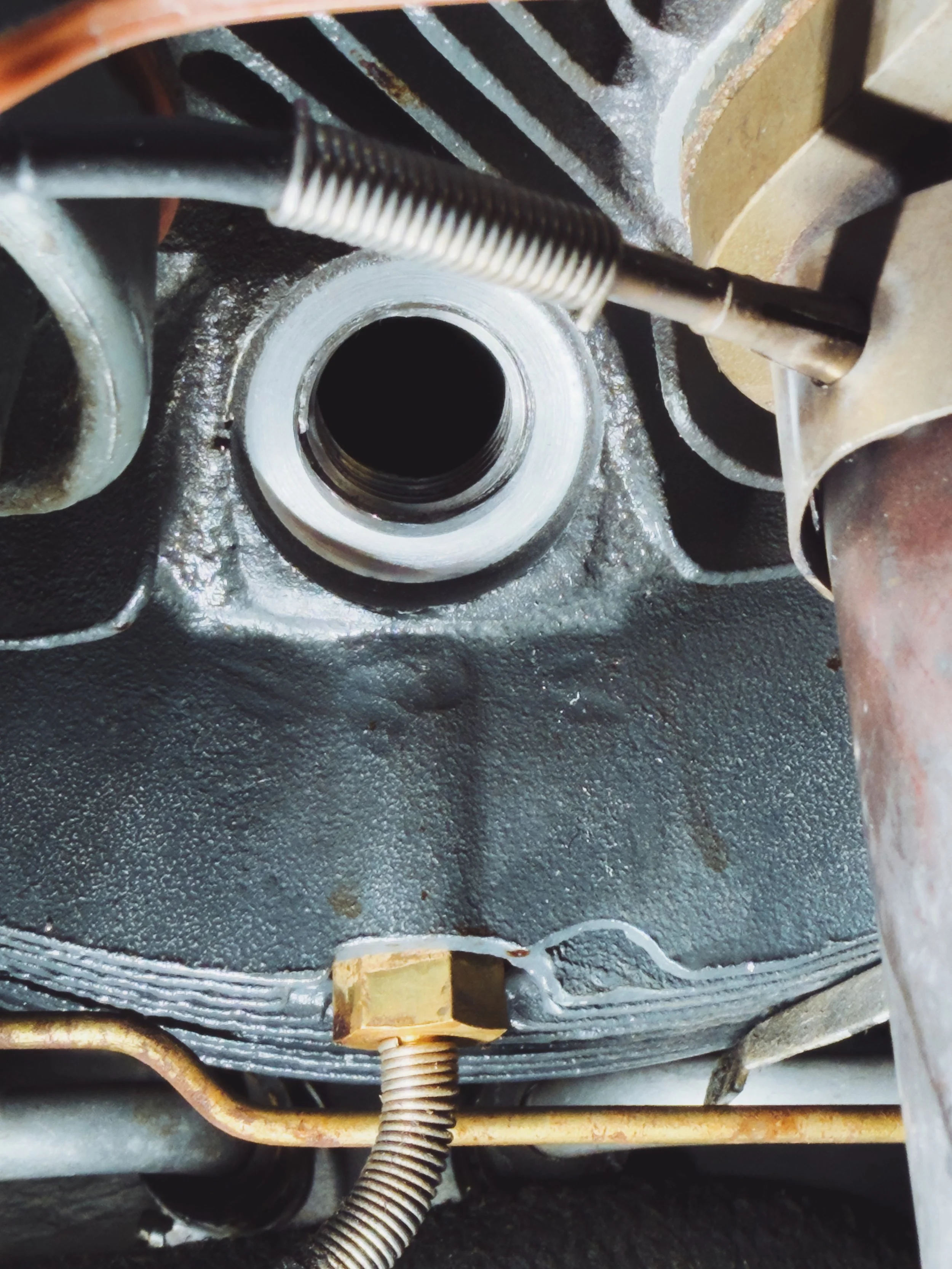

Then comes the physical inspection. Panels come off, seats may come out, and cowling is removed so we can see what matters.

From nose to tail, we look at:

Engine, mounts, and accessories

Fuel and induction systems

Control cables, linkages, and pulleys

Landing gear, tires, and brakes

Structure and corrosion-prone areas

Electrical wiring and connections

Anything questionable gets documented and photographed so we can clearly show and explain it to you — not just tell you.

Step 3: Clear communication — no surprises

Once the inspection is complete, we review everything with you.

We separate findings into:

Required — items needed for airworthiness

Recommended — smart preventive fixes

Monitor — safe to keep an eye on for now

You get the information, the context, and the options. Our job is to educate — not pressure.

Step 4: Correct, verify, and sign off

Approved repairs are completed, tested, inspected again, and documented thoroughly in the logs.

When Pacific Aviation Solutions signs off your aircraft, our name is in the book — and we take that responsibility seriously.

Tips to make your next annual smoother (and usually cheaper)

A few simple habits go a long way:

✔ Fix squawks as they come up — don’t save them all for the annual

✔ Keep your logbooks organized and complete

✔ Wash and dry the aircraft regularly to help prevent corrosion

✔ Ask questions — informed owners make great maintenance partners

We love when owners are curious and involved.

Final thought

Whether it’s a Cessna trainer, a Piper cruiser, a Beechcraft traveler, or a Van’s RV project you’ve poured your heart into — your aircraft deserves meticulous, transparent care.

At Pacific Aviation Solutions, we’re happy to explain every step, show you what we’re seeing, and help you feel confident in the air and on the ground.

If you’d like a walkthrough during your next annual — just ask. We’re always glad to open the hangar doors and show you around.